Rethinking Industrial Decarbonization

Rethinking Industrial Decarbonization

Flexible membrane and plasma systems for carbon and hydrogen conversion.

Flexible membrane and plasma systems for carbon and hydrogen conversion.

Flexible membrane and plasma systems for carbon and hydrogen conversion.

Scalable membrane and plasma systems for industrial carbon and hydrogen conversion.

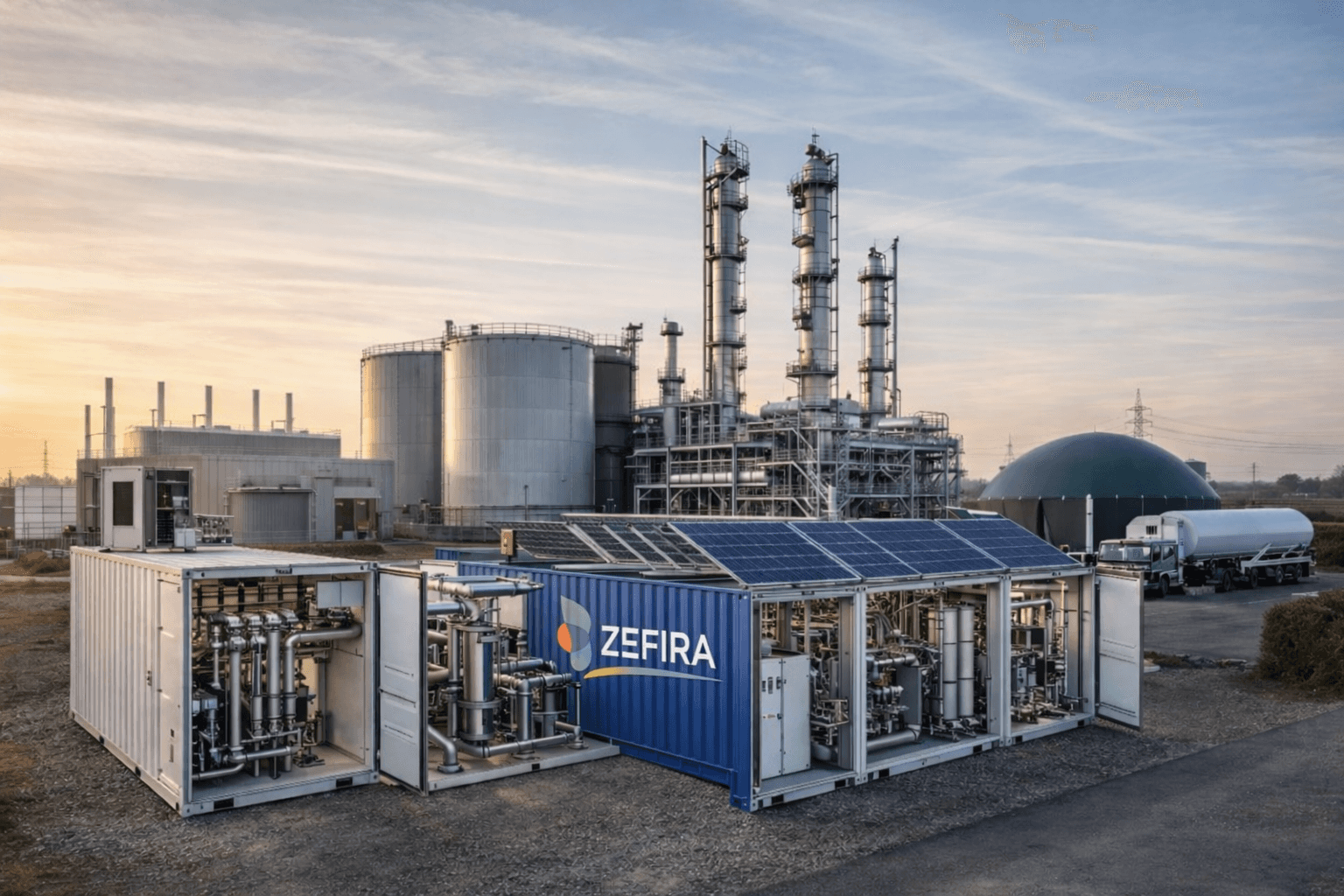

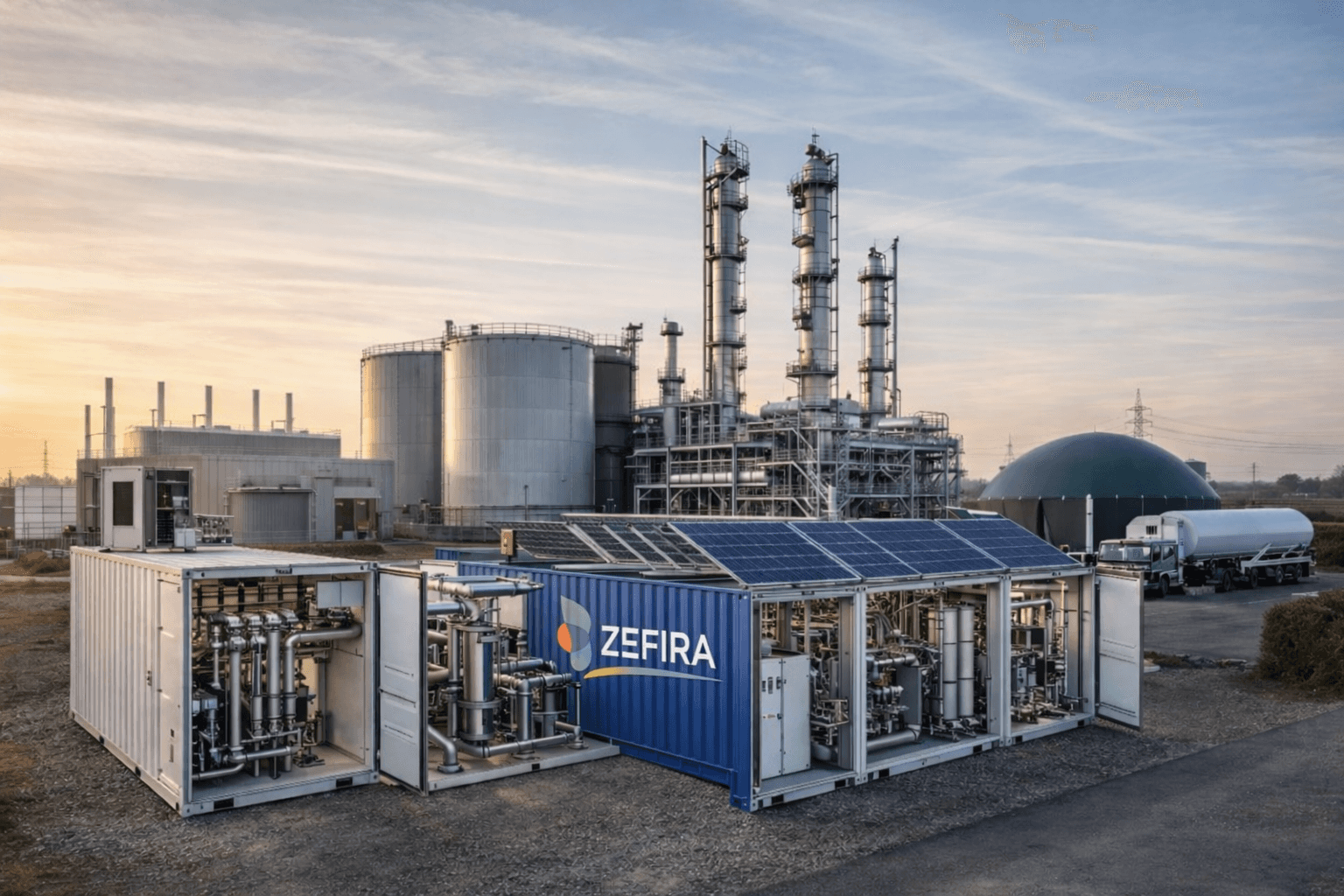

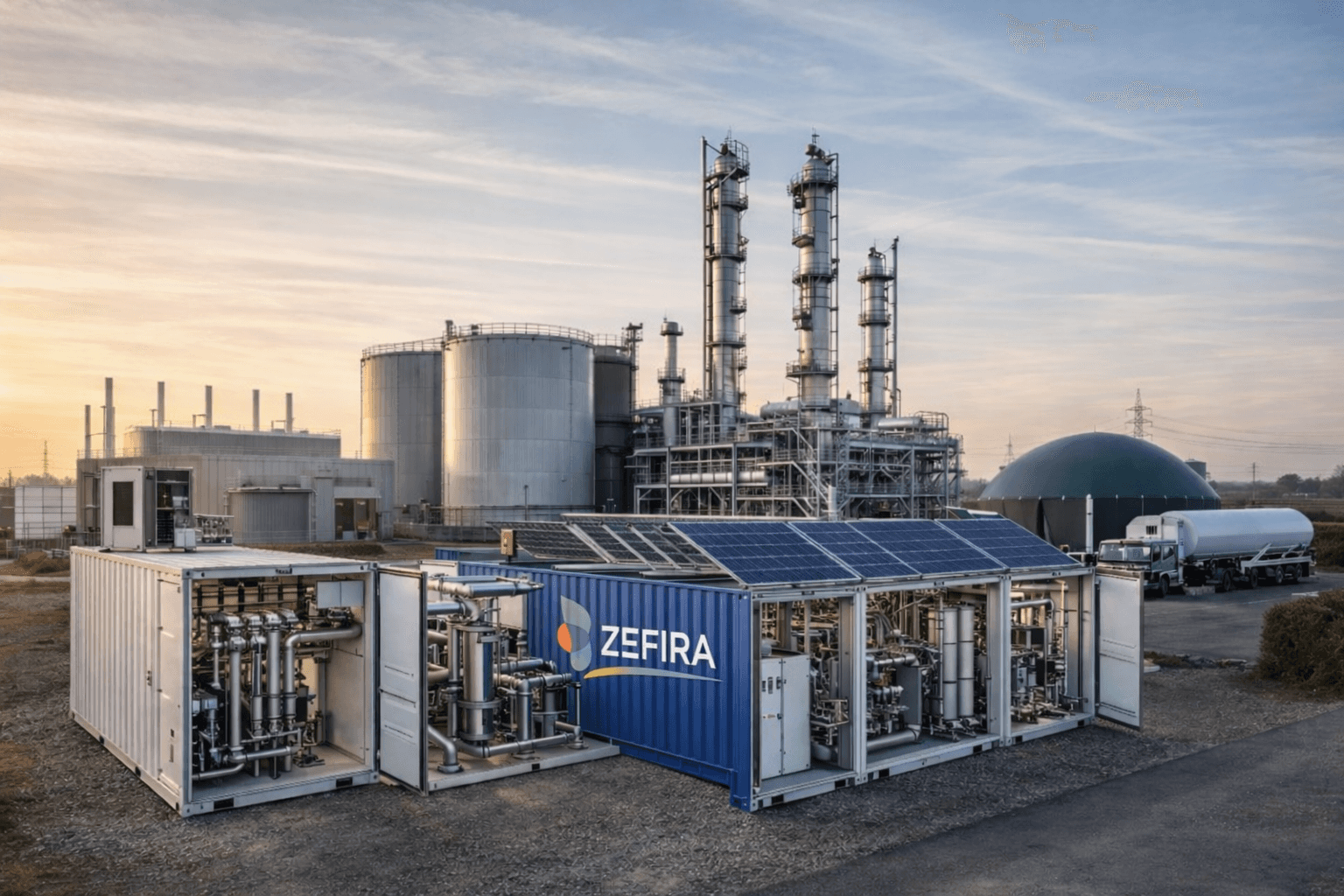

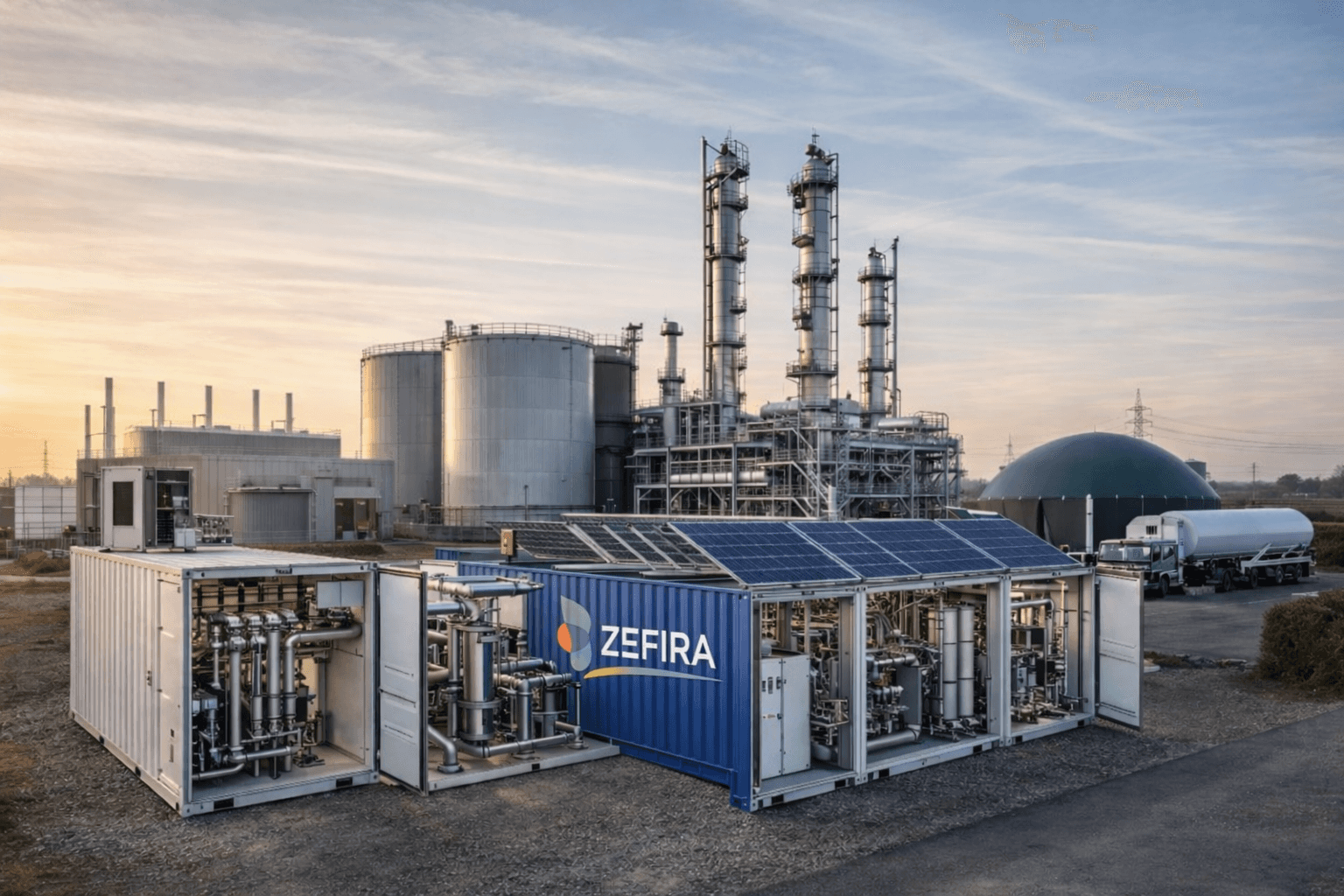

ZEFIRA enables the shift from fossil-based to renewable-based production through flexible, modular, and electrified process technologies.

Closing the Carbon Loop

Closing the Carbon Loop

From Carbon to Value

Global industries are entering a new era: they must cut emissions, replace fossil feedstocks, and operate alongside variable renewable energy.

Industry must decarbonize while remaining competitive.

Large, centralized plants can’t do it alone.

Large, centralized plants can’t do it alone.

Large, centralized plants can’t do it alone.

The next generation of energy and materials will rely on compact, flexible, and circular process systems that recover and convert CO₂ and biogenic resources into fuels and feedstocks.

ZEFIRA builds modular membrane and plasma systems that capture & convert CO₂ and low-value streams into fuels and feedstocks.

ZEFIRA builds these systems — designing modular process solutions that combine advanced membranes, membrane reactors, and plasma technologies to enable circular carbon and hydrogen pathways.

ZEFIRA builds these systems — designing modular process solutions that combine advanced membranes and plasma technologies to enable circular carbon and hydrogen pathways.

The Challenge

The Challenge

The Challenge

The Challenge

A New Paradigm for Industrial Processes

A New Paradigm for Industrial Processes

Hard-to-abate sectors — from steel and chemicals to aviation and shipping — still depend on fossil feedstocks and rigid infrastructures that can’t adapt to variable renewable energy. Meanwhile, sustainable carbon sources such as biomass and captured CO₂ remain scarce and unevenly distributed.

Hard-to-abate sectors — from steel and chemicals to aviation and shipping — still depend on fossil feedstocks

Heavy industry still depends on fossil inputs and rigid plants that can’t follow renewable energy.

To meet climate and competitiveness goals, industrial systems must become:

To meet climate goals, industrial systems must become:

Industry must become flexible, circular, and modular.

Flexible, to follow renewable power and demand fluctuations

Circular, to recover and reuse carbon and hydrogen instead of consuming new fossil inputs

Modular, to scale locally and integrate directly into existing plants

Flexible, to follow renewable power and demand fluctuations

Circular, to recover and reuse carbon and hydrogen instead of consuming new fossil inputs

Modular, to scale locally and integrate into existing plants

Without this shift, deep decarbonization will remain out of reach.

Without this shift, decarbonization won’t happen.

Our Approach

Our Approach

Our Approach

Our Approach

From Centralized to Modular — From Static to Flexible

ZEFIRA designs and integrates compact, high-performance process systems that unite efficiency with adaptability.

ZEFIRA builds compact, flexible industrial systems designed for a renewable-powered world.

Our approach is built on three core principles:

Our platform is based on:

Integration : coupling separation and reaction in intensified membrane and membrane-reactor units.

Integration : coupling separation and reaction in intensified reactors

Integration — separation and reaction in one unit

Electrification : replacing fired and heat-driven operations with electricity-powered systems compatible with renewable energy.

Electrification : replacing fired and heat-driven operations with electricity-powered systems compatible with renewable energy.

Electrification — processes powered by electricity, not flames

Scalability : enabling distributed, modular production of renewable fuels, chemicals, and feedstocks directly at industrial sites.

Scalability : enabling distributed, modular production of renewable fuels and chemicals

Scalability — modular systems deployed directly on-site

Together, these principles make deep decarbonization practical, efficient, and economically viable today.

Together, these principles make decarbonization possible

This makes industrial decarbonization practical, flexible, and scalable.

Solution

Solution

Solution

Solution

Delivering Impact Where It Matters Most

ZEFIRA’s modular, electrified systems enable deep decarbonization across the carbon and hydrogen value chains, helping industries cut emissions and energy use today.

ZEFIRA’s modular, electrified systems enable decarbonization across the carbon and hydrogen value chains

ZEFIRA deploys modular, electrified systems to cut emissions directly at industrial sites.

Steel & Heavy Industry — recover CO₂, separate H₂, and close the loop with circular syngas recycling.

Steel & Heavy Industry — recover CO₂, separate H₂, and close the loop with circular syngas recycling.

Steel & Heavy Industry — Circular carbon recovery and syngas recycling.

Aviation & Shipping — produce renewable methanol, DME, and SAF intermediates for next generation fuels.

Aviation & Shipping — produce renewable methanol, DME, and SAF intermediates for next generation fuels.

Aviation & Shipping — Renewable methanol, DME, and SAF intermediates.

Biogas & Waste — upgrade biogenic streams, capture CO₂, and synthesize renewable fuels on site.

Biogas & Waste — upgrade biogenic streams, capture CO₂, and synthesize renewable fuels on site.

Biogas & Waste — On-site CO₂ capture and fuel synthesis from biogenic streams.

Result: measurable emission reductions, lower energy consumption, and improved carbon efficiency delivered through compact, flexible systems ready for industrial integration.

Result : measurable emission reductions, lower energy consumption, and improved carbon efficiency

Result: lower emissions, lower energy use, measurable industrial impact.

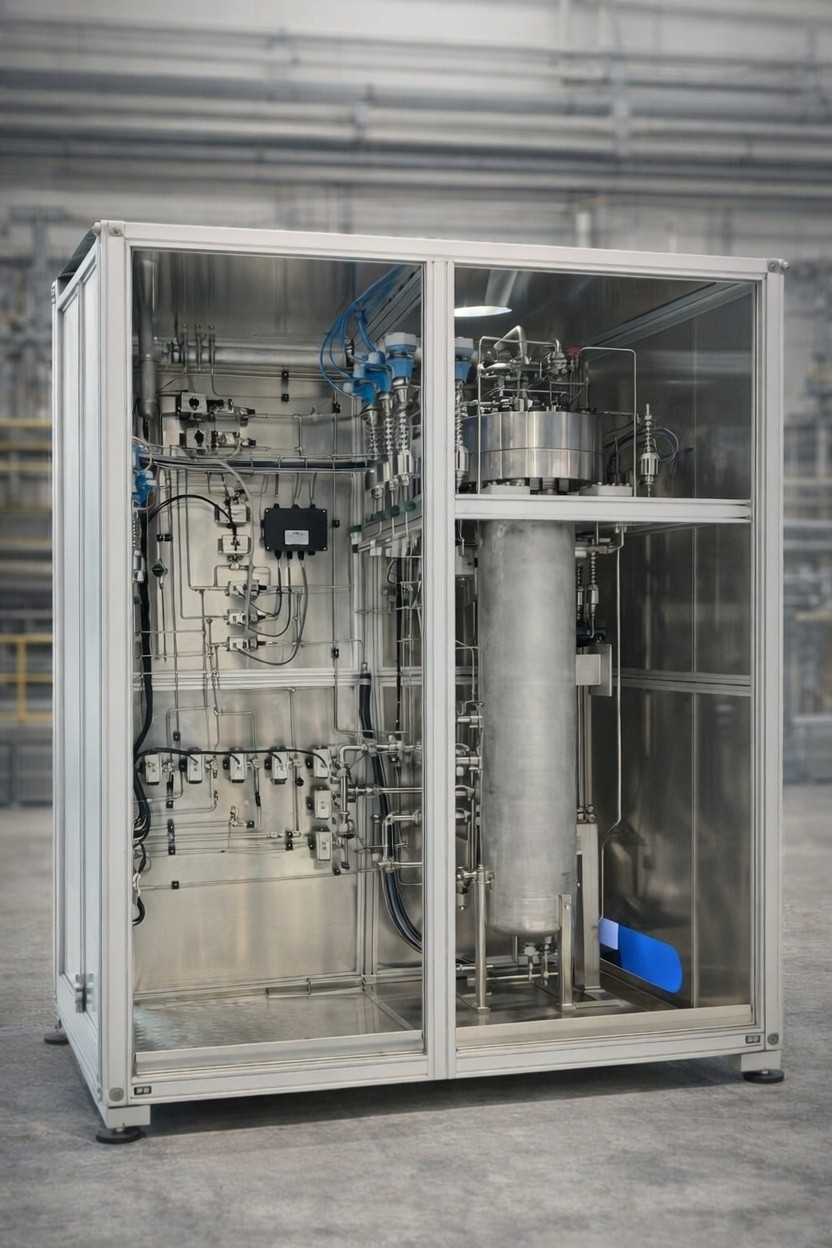

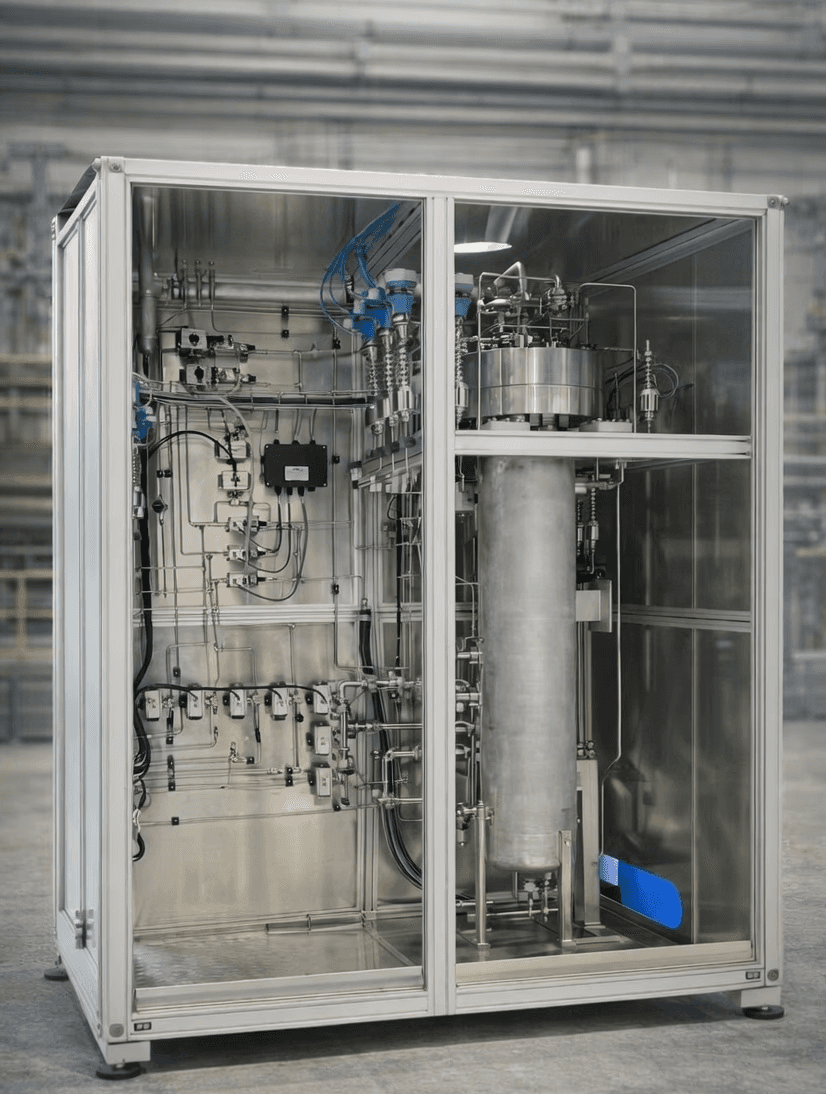

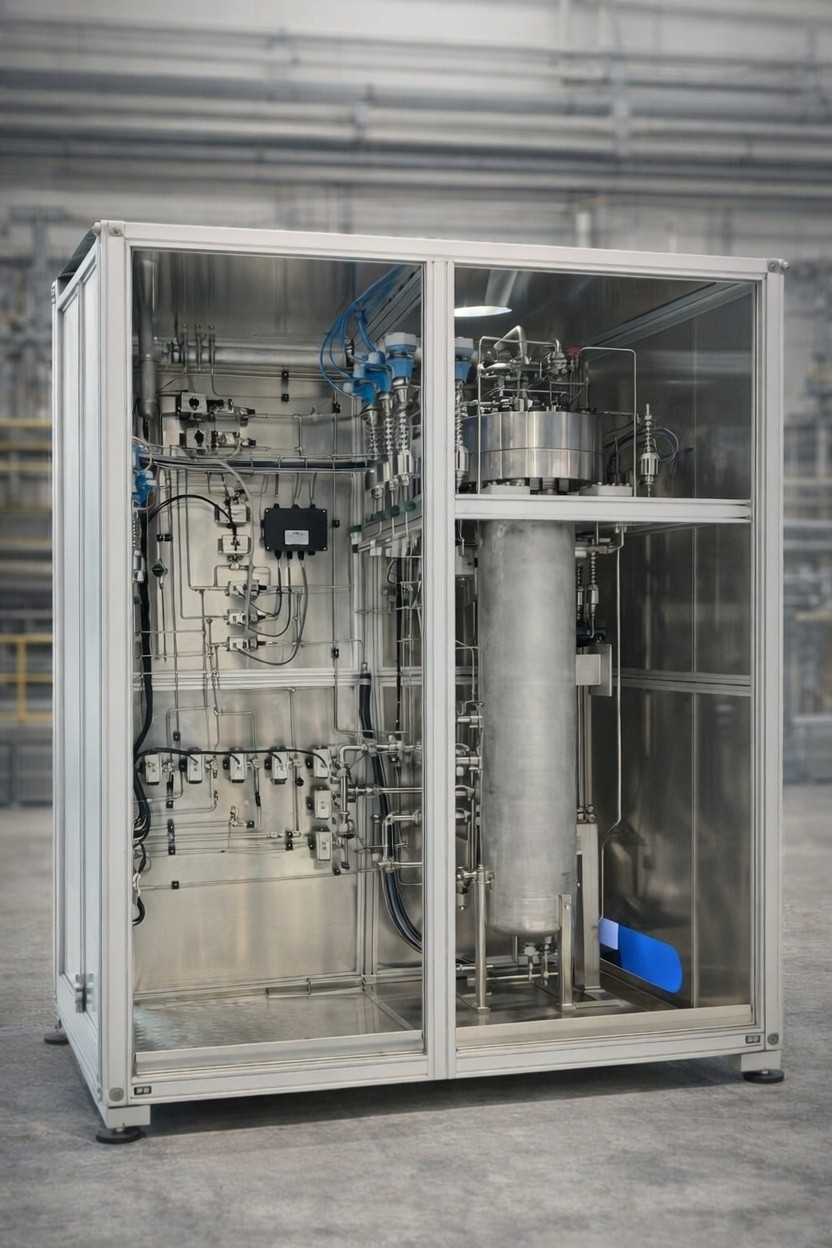

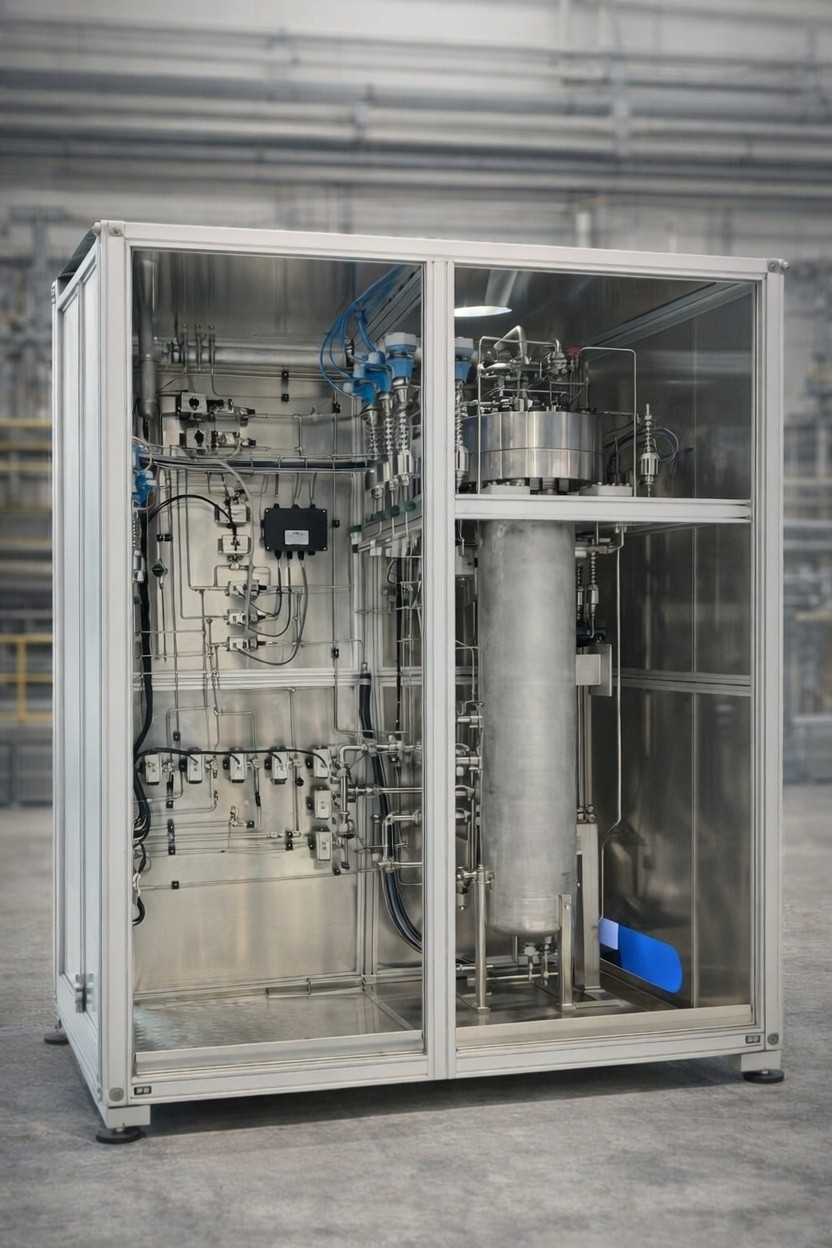

Our Membrane Technology

Our Membrane Technology

Our Membrane Technology

Our Membrane Technology

Industrial-Ready Today, Evolving for Tomorrow

Designed for Industrial Conditions

ZEFIRA develops advanced carbon membranes and membrane-reactor systems for gas separation and low-carbon fuel production across carbon and hydrogen value chains.

ZEFIRA develops advanced carbon membranes and membrane-reactor systems for gas separation and low-carbon fuel production.

These membrane technologies are designed for robust operation, modular integration, and compatibility with industrial process environments, supporting flexible and efficient conversion pathways.

Together, they form a scalable membrane technology platform designed for integration into next-generation low-carbon industrial processes.

These membrane technologies are designed for robust operation, modular integration, and compatibility with industrial process environments, supporting flexible and efficient conversion.

Together, they form a scalable membrane technology platform designed for integration into next-generation industrial processes.

Designed for robust industrial operation, modular integration, and scalable deployment across carbon and hydrogen value chains.

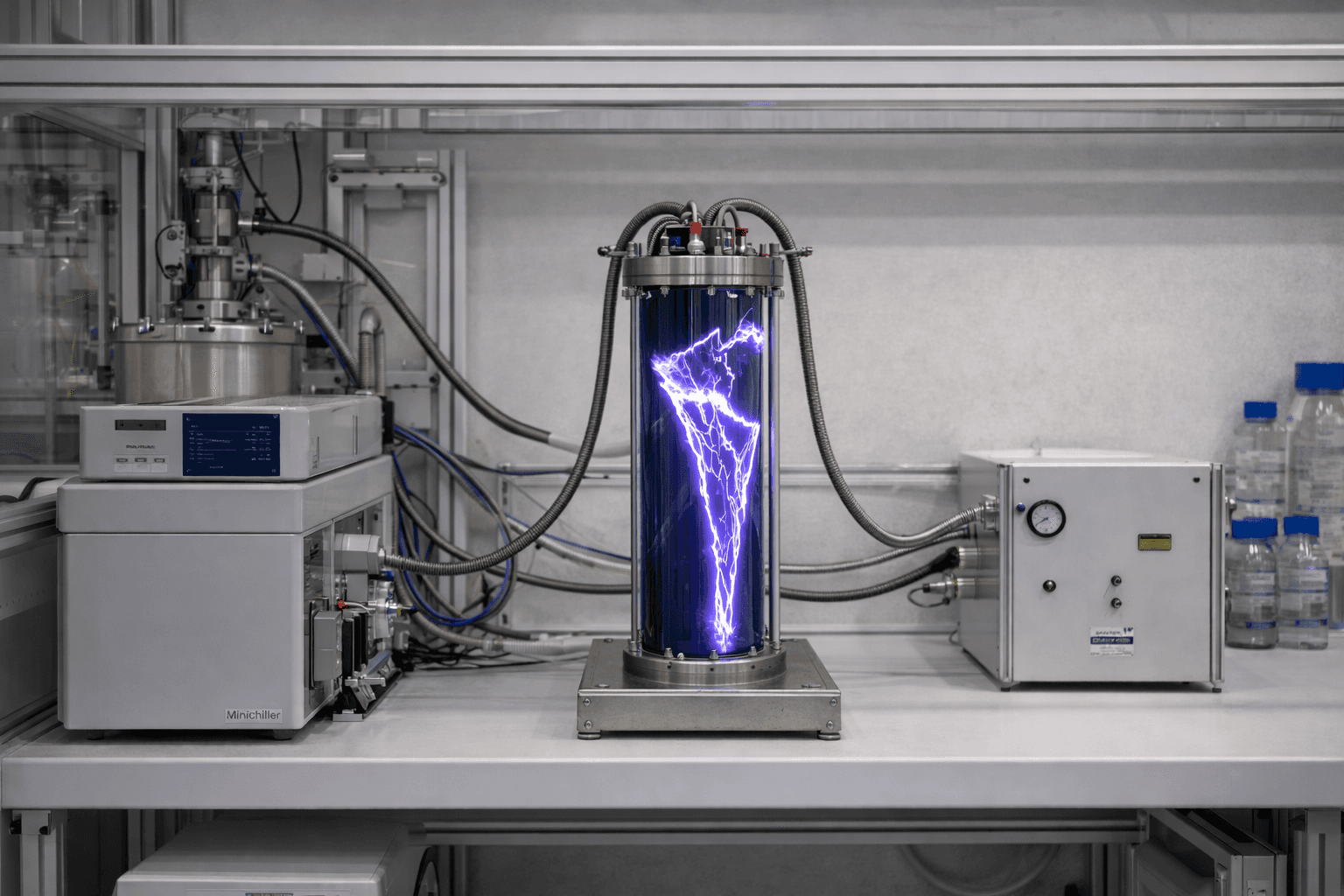

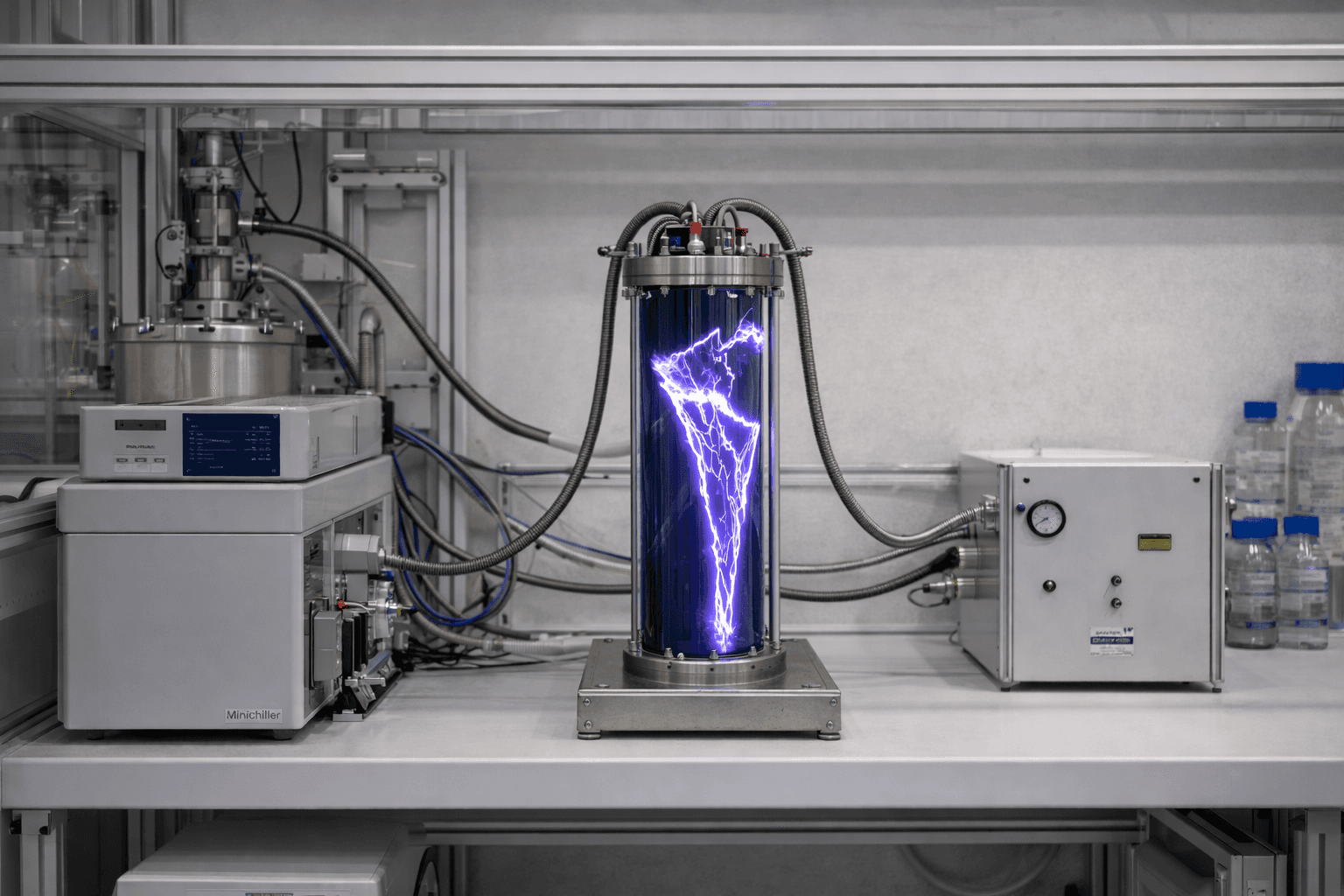

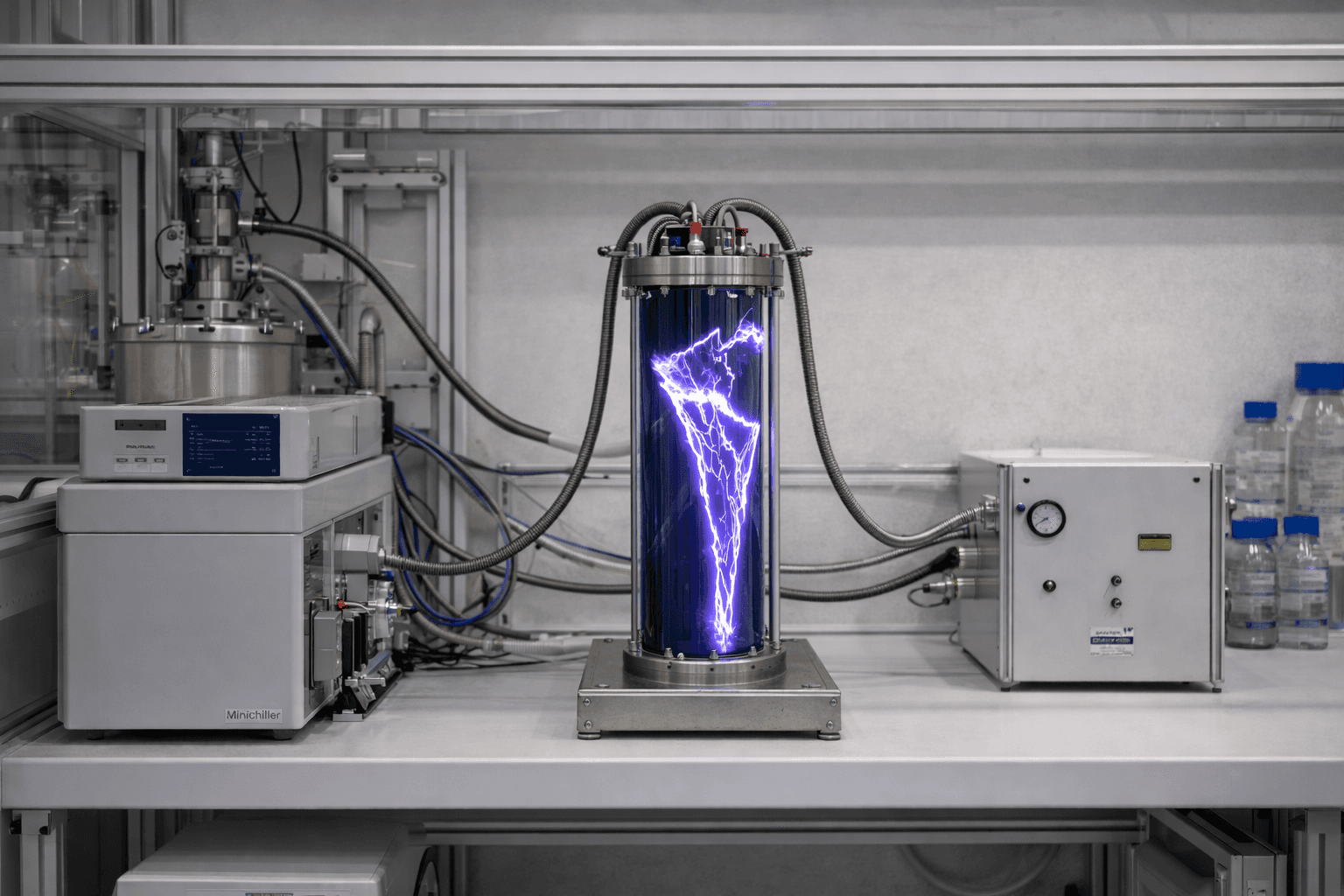

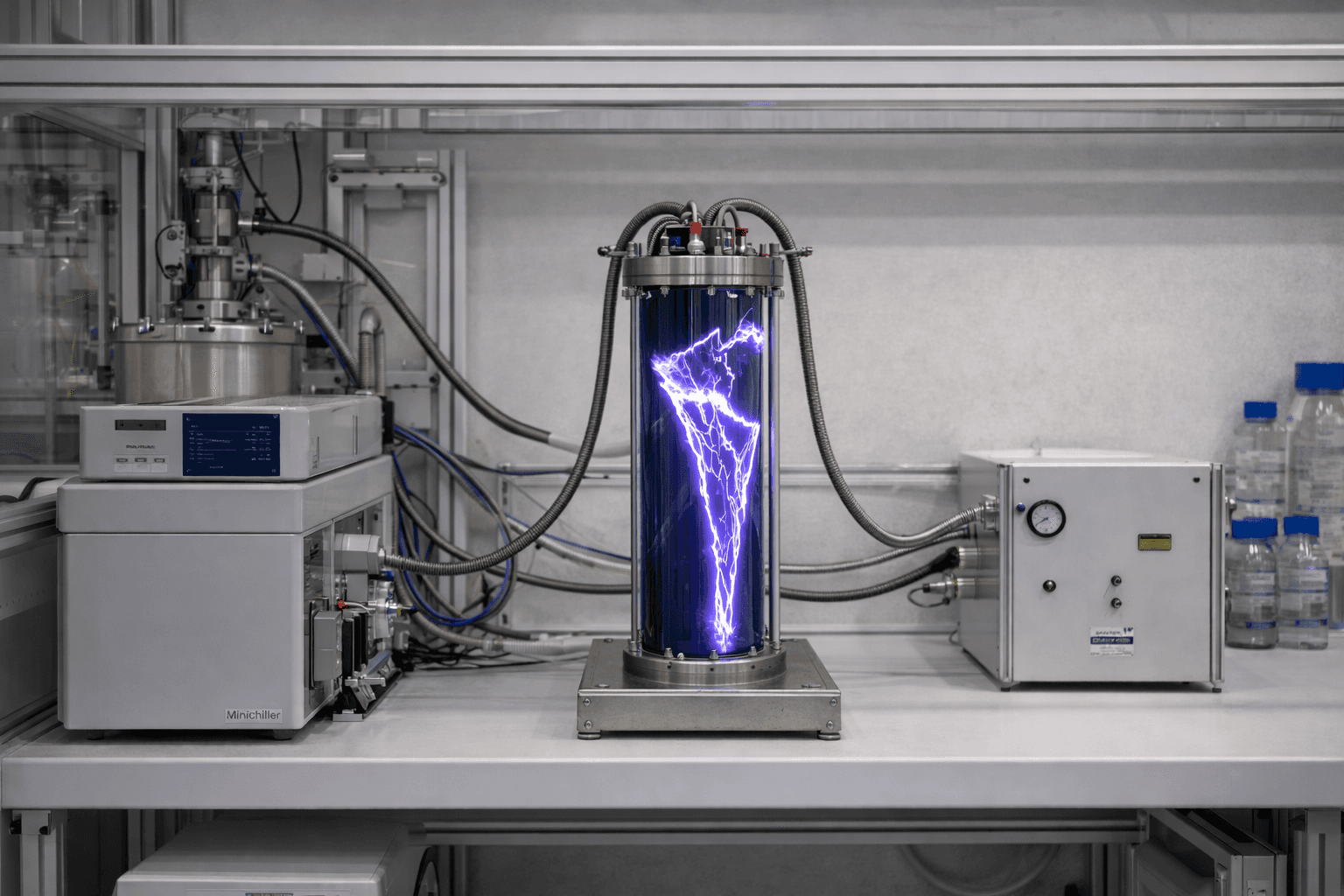

Our Plasma Technology

Our Plasma Technology

Our Plasma Technology

Our Plasma Technology

Electrifying the Carbon Cycle

Building on its reactor and integration expertise, ZEFIRA develops plasma-based conversion technologies that use renewable electricity to transform carbon molecules.

ZEFIRA develops plasma-based conversion systems that use renewable electricity to transform carbon molecules.

ZEFIRA focuses on plasma pathways for:

Biogas dry reforming, converting biogenic methane and CO₂ into syngas

Direct CO₂-to-CO conversion, enabling electrified carbon recycling

These fully electrified systems support Biogas-to-X and Power-to-X pathways, combining operational flexibility with modular reactor design for circular-carbon applications.

These modular, fully electrified reactors enable Power-to-X and Biogas-to-X applications.

Trusted Partnerships

Trusted Partnerships

Trusted Partnerships

Trusted Partnerships

Rooted in Science, Built with Industry

Founded in 2025 and based in Eindhoven, ZEFIRA builds on more than 15 years of research at Eindhoven University of Technology (TU/e). We partner with leading universities, industrial innovators, and European programmes to bridge the gap between laboratory breakthroughs and large-scale deployment.

Born from 15+ years of research at TU/e.

Built with industrial partners to scale real solutions.

News

News

News

News

Latest News

Latest News

Jan 12, 2026

Fausto Gallucci

ZEFIRA Meets TECNALIA in Bilbao to Explore Strategic Collaboration

Jan 12, 2026

Fausto Gallucci

ZEFIRA Meets TECNALIA in Bilbao to Explore Strategic Collaboration

Jan 12, 2026

Fausto Gallucci

ZEFIRA Meets TECNALIA in Bilbao to Explore Strategic Collaboration

Jan 5, 2026

Camel Makhloufi

New paper on methanol production from our CTO

Jan 5, 2026

Camel Makhloufi

New paper on methanol production from our CTO

Jan 5, 2026

Camel Makhloufi

New paper on methanol production from our CTO

Dec 3, 2025

ZEFIRA Meets with TU/e Leadership to Strengthen Strategic Collaboration

Dec 3, 2025

ZEFIRA Meets with TU/e Leadership to Strengthen Strategic Collaboration

Dec 3, 2025

ZEFIRA Meets with TU/e Leadership to Strengthen Strategic Collaboration

Engineering the Transition Together

We collaborate with industrial partners, technology developers, and investors to bring membrane and plasma-based solutions to low-carbon industrial applications.

Get in touch to explore collaboration, pilot testing, or investment opportunities with ZEFIRA.

Engineering the Transition Together

We collaborate with industrial partners, technology developers, and investors to bring membrane and plasma-based solutions to low-carbon industrial applications.

Get in touch to explore collaboration, pilot testing, or investment opportunities with ZEFIRA.

Engineering the Transition Together

We collaborate with industrial partners, technology developers, and investors to bring membrane and plasma-based solutions to low-carbon industrial applications.

Get in touch to explore collaboration, pilot testing, or investment opportunities with ZEFIRA.

Engineering the Transition Together

We collaborate with industrial partners, technology developers, and investors to bring membrane and plasma-based solutions to low-carbon industrial applications.

Get in touch to explore collaboration, pilot testing, or investment opportunities with ZEFIRA.