Membrane Technology

Membrane Technology

Membrane Technology

Unique Technology for the Carbon and Hydrogen Economy

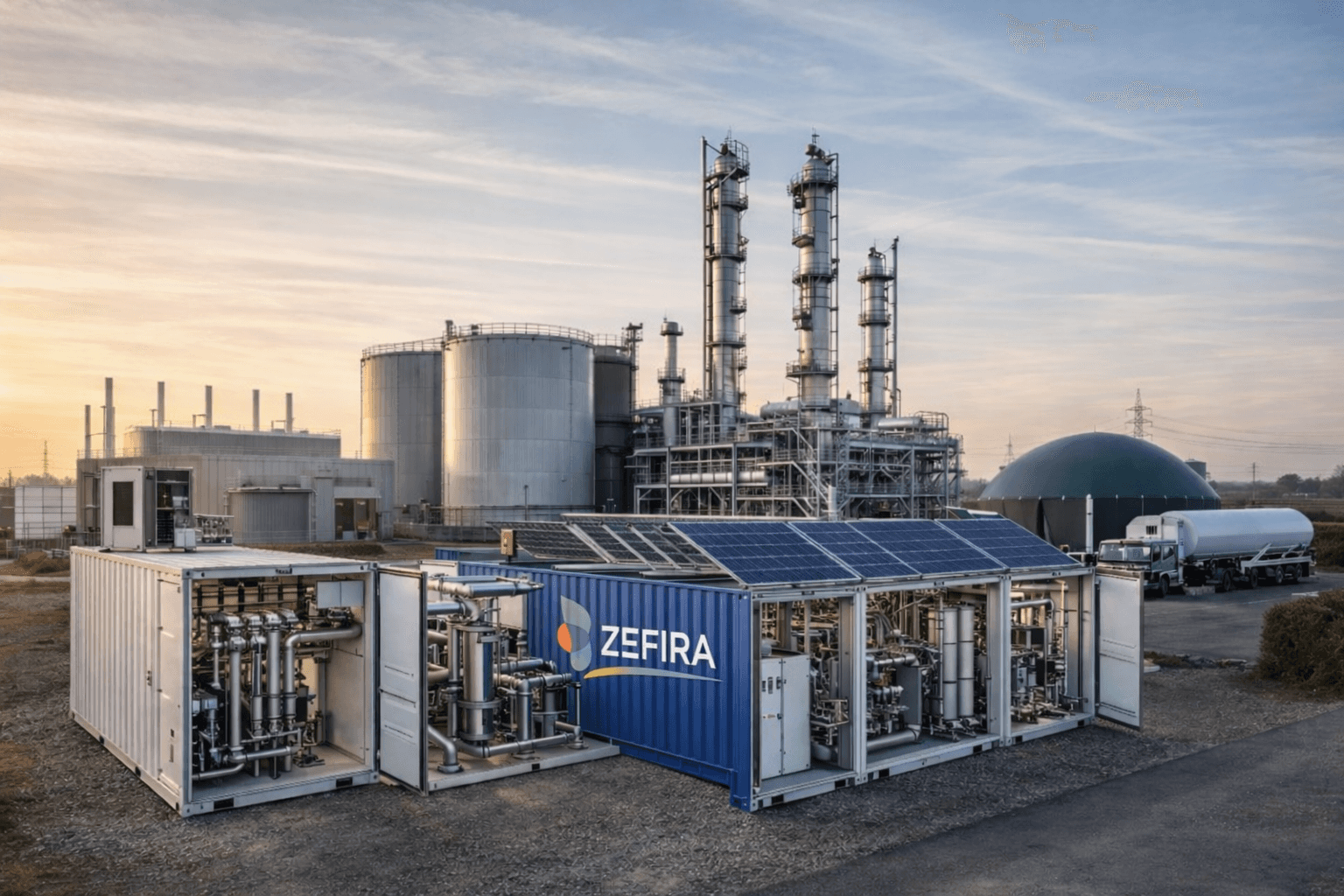

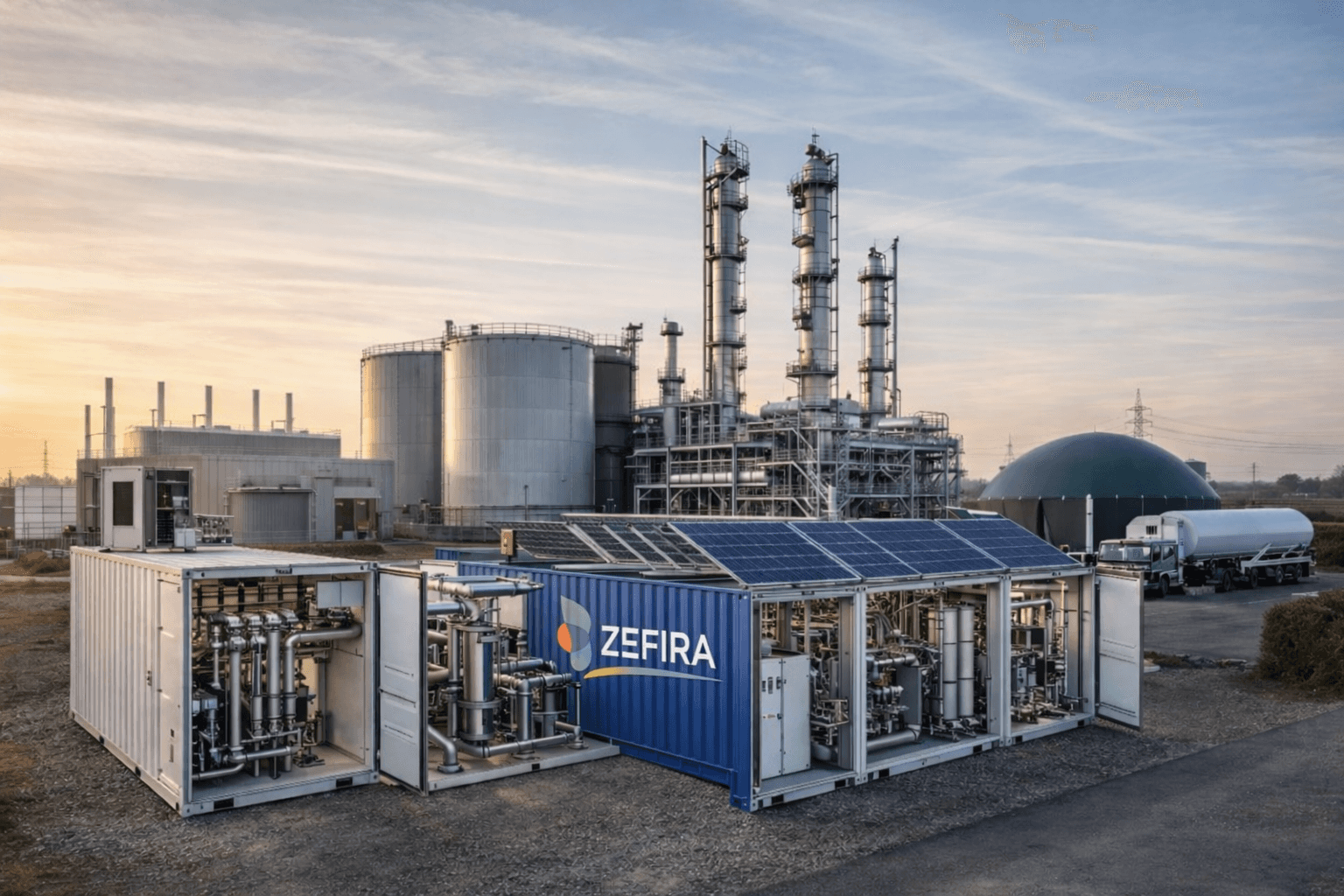

ZEFIRA’s carbon-membrane platform delivers industrial-grade performance for CO₂ capture, hydrogen recovery, and fuel synthesis. It provides a modular and scalable foundation for defossilizing critical industrial processes from chemical conversion to renewable-fuel production.

Membrane Technology

Unique Technology for the Carbon and Hydrogen Economy

ZEFIRA develops selective carbon membranes that enable efficient gas separation and conversion for low-carbon fuels and hydrogen pathways.

What Makes It Different

What Makes It Different

What Makes It Different

What Makes It Different

Compact, Efficient, Circular

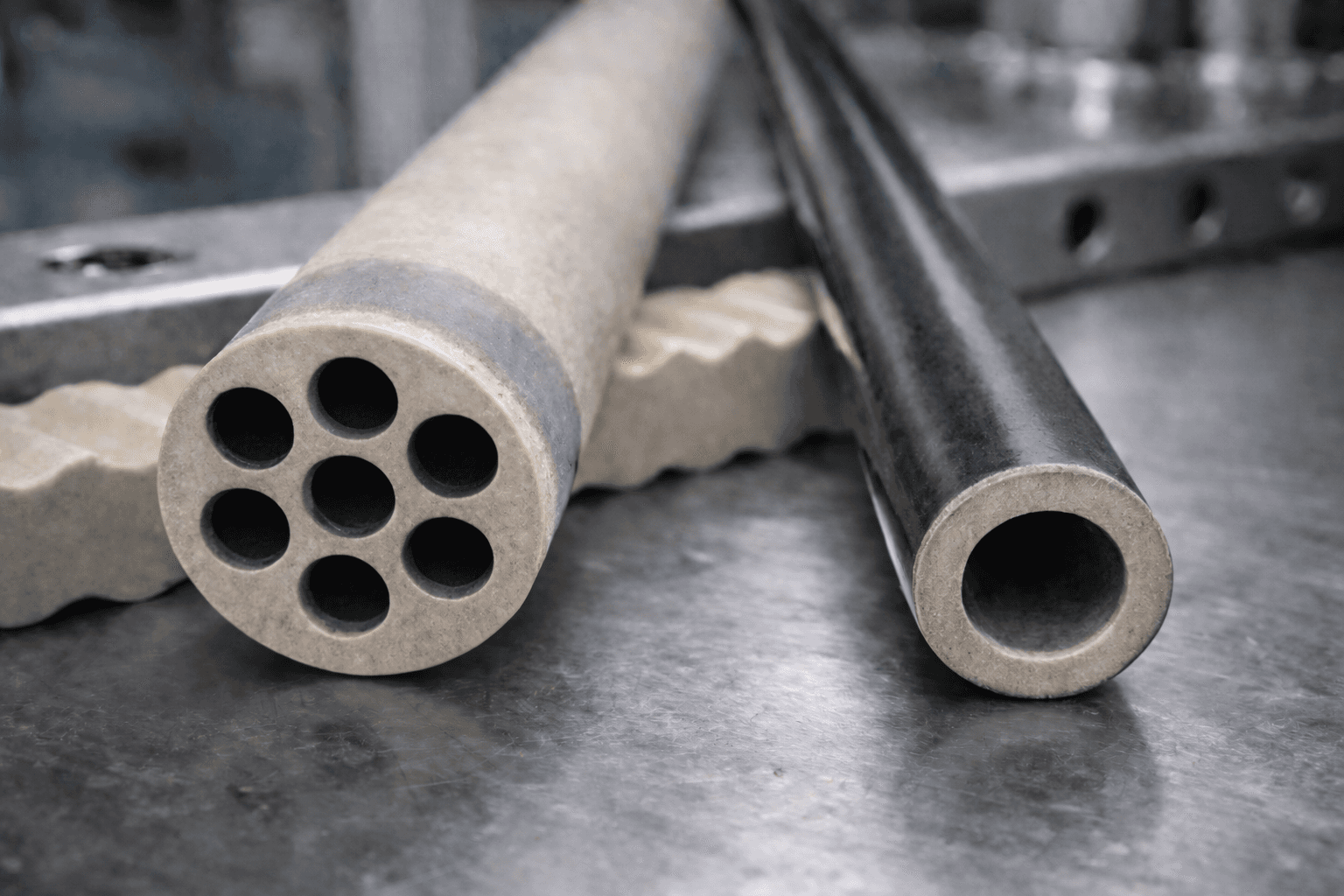

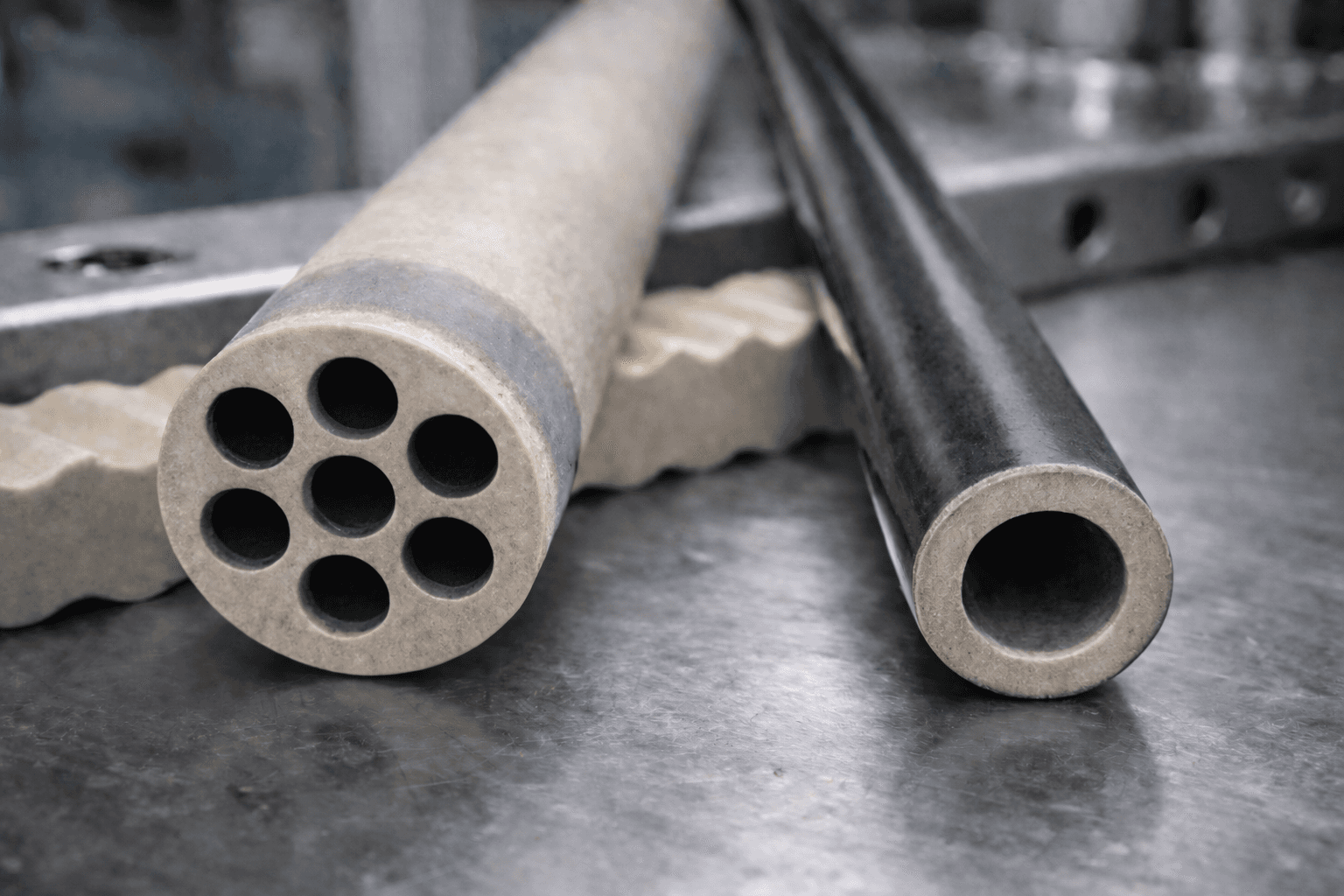

ZEFIRA’s carbon membranes act as selective molecular filters, allowing target gases (CO₂, H₂, H₂O) to pass while retaining others. This enables cleaner separations and more efficient reactions with less energy and smaller systems.

ZEFIRA’s carbon membranes act as selective molecular filters, enabling clean separations and efficient reactions with less energy and smaller systems.

ZEFIRA’s membranes selectively separate CO₂, H₂, and H₂O, enabling separations and more efficient reactions with lower energy use.

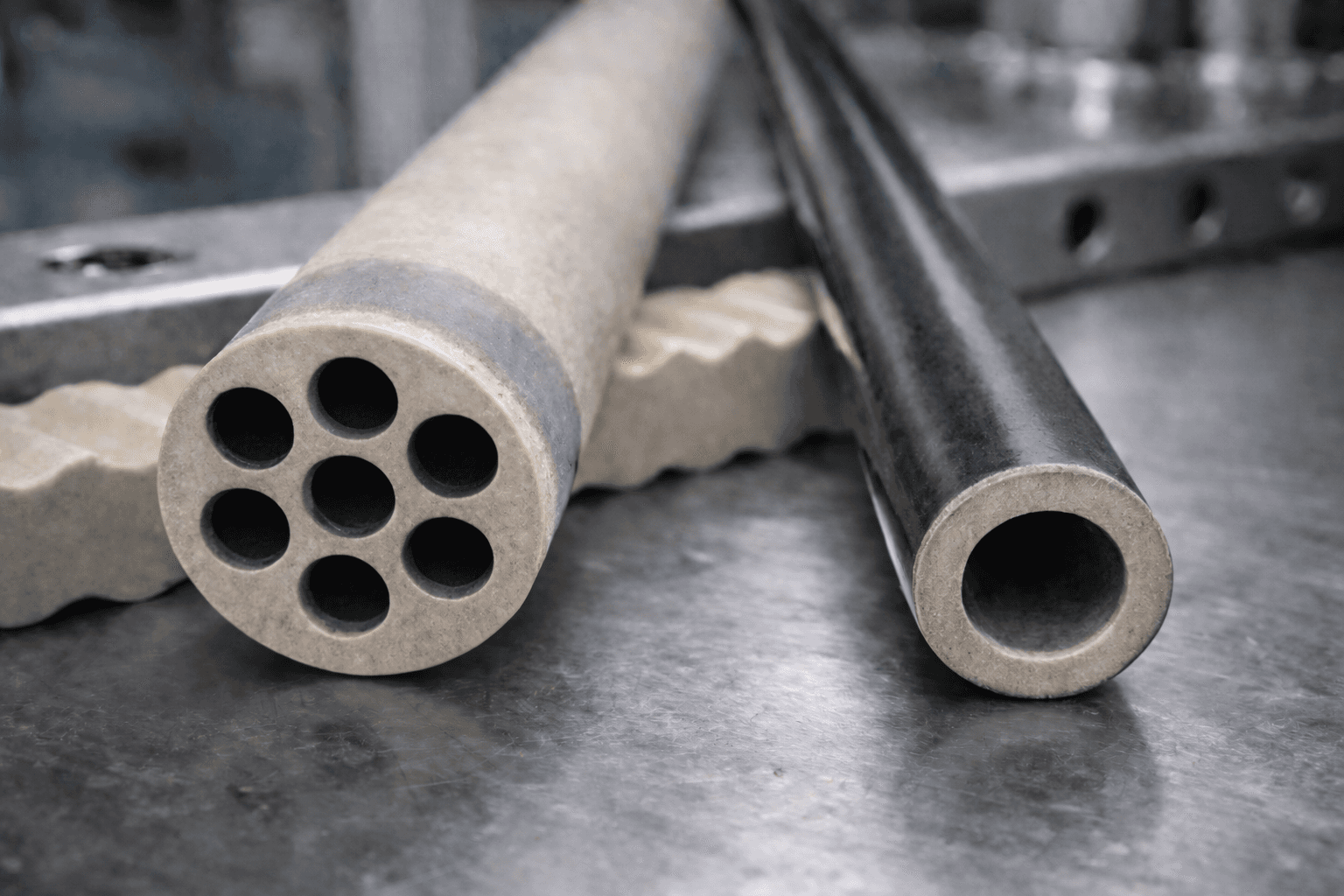

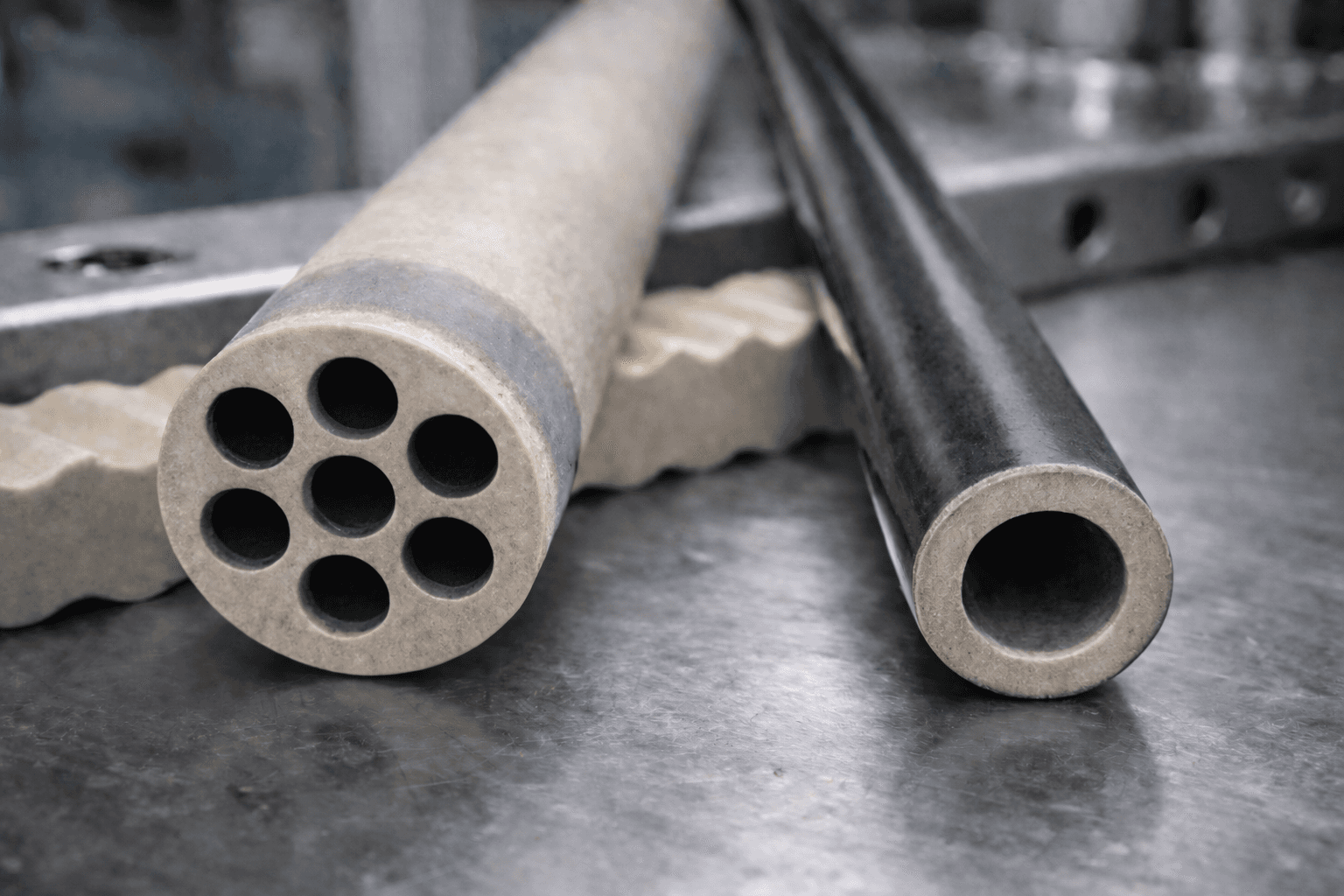

ZEFIRA’s carbon molecular sieve (CMS) membranes combine high performance, resilience, and sustainability in a single technology:

ZEFIRA’s carbon molecular sieve (CMS) membranes offer :

ZEFIRA’s membranes combine performance, resilience, and sustainability:

Extreme chemical stability — tolerant to moisture, sulfur, and organic impurities

High chemical stability — tolerant to moisture, sulfur, and impurities

Extreme chemical stability — tolerant to moisture and impurities

Broad operating range — from vacuum to 120 bar and up to 700 °C

Wide operating range — from vacuum to high pressure and temperature

Broad operating range — up to 120 bar & 700 °C

Tunable selectivity — adaptable to each gas mixture and process condition

Tunable selectivity — adaptable to different gas mixtures

Tunable selectivity — adapted to gas mixtures and conditions

Long-term durability — built without critical raw materials and designed for recyclability

Long-term durability — no critical raw materials, recyclable by design

Long-term durability — recyclable, no critical raw materials

The result: higher yield, lower energy use, and simplified system design compared with conventional separation or reaction units.

The result: higher yields, lower energy use, and simpler system architectures.

Result: higher yield, lower energy use, and simpler system design.

Core Capabilities

Core Capabilities

Core Capabilities

Core Capabilities

One Platform, versatile Functions

ZEFIRA’s membrane platform supports multiple process functions across the carbon and hydrogen value chains:

CO2 and Hydrogen separation

High-temperature carbon membranes for efficient CO₂ and H₂ separation — tolerant to impurities and designed for demanding industrial conditions.

CO2 and Hydrogen separation

High-temperature carbon membranes for efficient CO₂ and H₂ separation — tolerant to impurities and designed for demanding industrial conditions.

CO2 and Hydrogen separation

High-temperature carbon membranes for efficient CO₂ and H₂ separation — tolerant to impurities and designed for demanding industrial conditions.

CO2 and Hydrogen separation

High-temperature carbon membranes for efficient CO₂ and H₂ separation — tolerant to impurities and designed for demanding industrial conditions.

Tailored Membranes for Advanced Gas & Liquid Separation

Custom-engineered carbon membranes with controlled pore size and surface polarity — adaptable from helium recovery to chemical purification.

Tailored Membranes for Gas & Liquid Separation

Custom-engineered carbon membranes with controlled pore size and surface polarity — adaptable from helium recovery to chemical purification.

Tailored Membranes for Advanced Gas & Liquid Separation

Custom-engineered carbon membranes with controlled pore size and surface polarity — adaptable from helium recovery to chemical purification.

Tailored Membranes for Advanced Gas & Liquid Separation

Custom-engineered carbon membranes with controlled pore size and surface polarity — adaptable from helium recovery to chemical purification.

Membrane Reactors for Fuel Synthesis

Water-selective membrane reactors that raise conversion per pass and cut recycle loads — enabling flexible, low-pressure e-fuel and biofuel production

Membrane Reactors for Fuel Synthesis

Water-selective membrane reactors that raise conversion per pass and cut recycle loads — enabling flexible, low-pressure e-fuel and biofuel production

Membrane Reactors for Fuel Synthesis

Water-selective membrane reactors that raise conversion per pass and cut recycle loads — enabling flexible, low-pressure e-fuel and biofuel production

Membrane Reactors for Fuel Synthesis

Water-selective membrane reactors that raise conversion per pass and cut recycle loads — enabling flexible, low-pressure e-fuel and biofuel production

Industrial Validation

Industrial Validation

Industrial Validation

Industrial Validation

Engineered for Industrial Deployment

ZEFIRA’s membrane systems have been tested under representative operating conditions, demonstrating performance and durability relevant to CO₂ capture, hydrogen recovery, and e-fuel synthesis.

Designed from the outset for scale-up and industrial integration, ZEFIRA’s technologies are progressing from laboratory and pilot-scale validation toward industrial demonstration.

Designed for real operating conditions and industrial integration.

Engineering the Transition Together

We collaborate with industrial partners, technology developers, and investors to bring membrane and plasma-based solutions to low-carbon industrial applications.

Get in touch to explore collaboration, pilot testing, or investment opportunities with ZEFIRA.

Engineering the Transition Together

We collaborate with industrial partners, technology developers, and investors to bring membrane and plasma-based solutions to low-carbon industrial applications.

Get in touch to explore collaboration, pilot testing, or investment opportunities with ZEFIRA.

Engineering the Transition Together

We collaborate with industrial partners, technology developers, and investors to bring membrane and plasma-based solutions to low-carbon industrial applications.

Get in touch to explore collaboration, pilot testing, or investment opportunities with ZEFIRA.

Engineering the Transition Together

We collaborate with industrial partners, technology developers, and investors to bring membrane and plasma-based solutions to low-carbon industrial applications.

Get in touch to explore collaboration, pilot testing, or investment opportunities with ZEFIRA.